The most common question we are asked is when to use a a +5% or a +2.5% Sheave Gauge.

The most common question we are asked is when to use a a +5% or a +2.5% Sheave Gauge.

The answer is:

- +5% Sheave Gauges are designed to determine optimal sheave geometry. They should fit snugly in new or re-machined sheaves. If correctly sized wire rope is run through the sheaves there will be a minimum of friction which should extend the life of the wire rope.

- +2.5% API Sheave Gauges are used to determine when Maximum and Excessive Wear levels has been reached.

In order to ensure optimal performance of sheaves and wire rope both type of gauges should be utilized.

| +5% NEW SHEAVE GAUGES |

+2.5% API SHEAVE GAUGES |

|

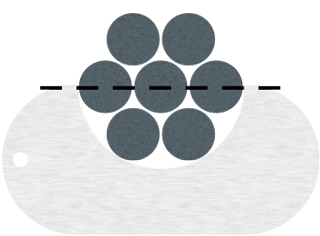

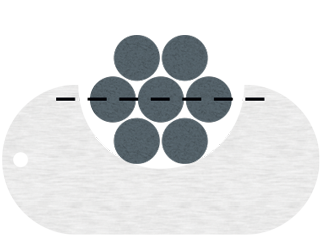

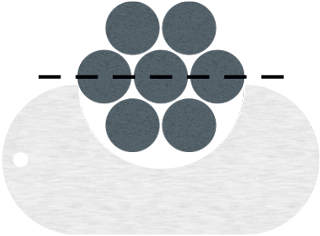

CORRECT

+5% Sheave Gauges should fit in New Sheaves without any gaps on the bottom or sides.

|

|

|

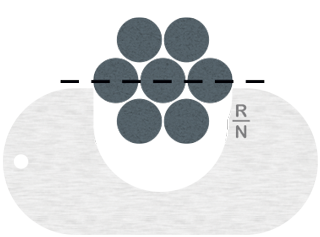

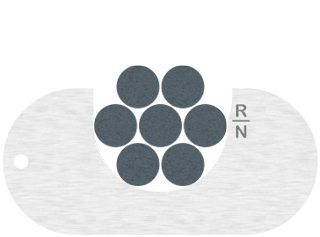

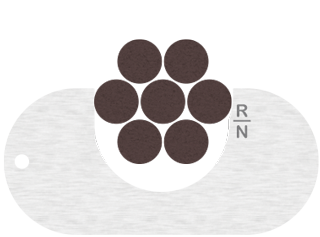

CORRECT

+2.5% Sheave Gauges should fit in a Sheave with some space on the side but without any gaps on the bottom.

|

|

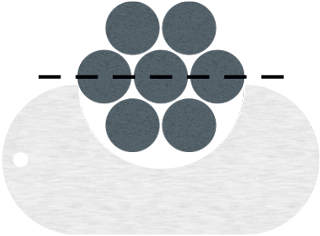

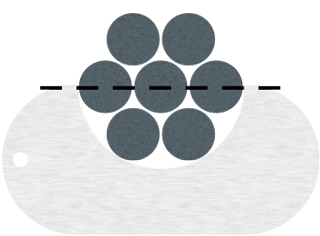

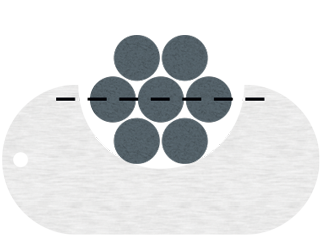

TOO LOOSE

Sheaves may become wider due to installation of oversized wire rope, wobble due to bearing collapse or due to excessive fleet angle.

|

|

|

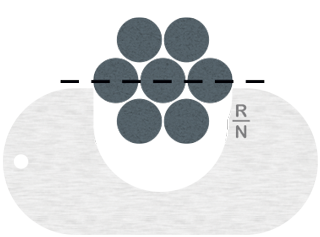

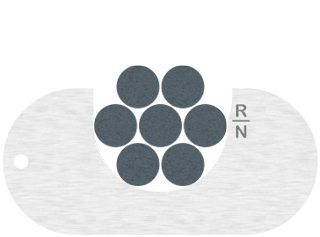

MAXIMUM WEAR

When a +2.5% Gauge fits in a Sheave without any space on the side or bottom it has reached it's maximum wear point and should be scheduled for replacement.

|

|

TOO TIGHT

If there is a gap below a +5% Gauge it may be excessively worn. Use a +2.5% Sheave Gauge to test if Maximum wear has been exceeded.

|

|

|

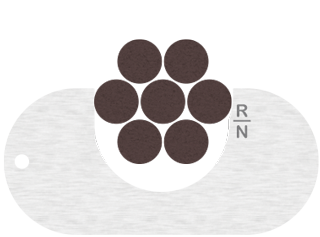

EXCESSIVE WEAR

A gap below a +2.5% Sheave Gauge indicates an excessively worn Sheave which should be removed from service at the next opportunity.

|

| NOMINAL WIRE GAUGES |

GO NO/GO WIRE GAUGES |

MEASURE ACROSS THE

OUTER EDGE OF TWO STRANDS

|

CORRECT

Wire Rope should not fit in Gauge

|

USE LARGER GAUGE

|

ROUGED WIRE ROPE

Replace if Cable Shows Rust

|

USE SMALLER GAUGE

|

REPLACE WIRE ROPE

When Cable Fits in Gauge

|

Using a Nominal

Wire Rope Gauge

Only use a wire rope gauge to determine approximate wire rope diameter.

- Align the gauge so that the wire can be measured from the outer edge of one strand to the edge of the strand directly opposite.

- If the wire rope does not fit in the gauge, use a larger gauge until the wire rope fits in the gauge.

- Shine a light behind the gauge.

- If you can see light between the gauge and the wire rope repeat with a smaller size gauge until no light shows.

For more accurate measurements use a machinist’s caliper or micrometer.

|

Using a Go/NoGo

Wire Rope Gauge

Only use a wire rope gauge to determine approximate wire rope diameter.

- Align the gauge so that the wire can be measured from the outer edge of one strand to the edge of the strand directly opposite.

- If the wire rope does not fit in the gauge it is still above the nominal -3.125% threshold.

- If the wire rope fits in the first notch it should be replaced if the cable shows rust (rouge).

- If the wire rope reaches to the bottom of the gauge it should be replaced.

For more accurate measurements use a machinist’s caliper or micrometer.

|

The most common question we are asked is when to use a a +5% or a +2.5% Sheave Gauge.

The most common question we are asked is when to use a a +5% or a +2.5% Sheave Gauge.